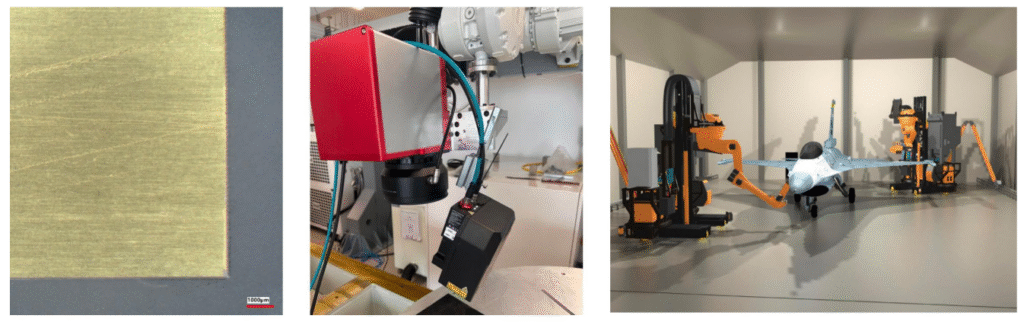

This system is built on a fully closed-loop intelligent laser platform specifically designed for non-destructive coating removal on aircraft skin. Experimental testing has determined the damage threshold of the anodized aircraft layer to be 2.83 J/cm², ensuring precise laser energy control without harming the underlying substrate. By integrating intelligent laser surface-processing technology, the system overcomes the limitations of traditional chemical stripping and mechanical abrasion, delivering a highly efficient, environmentally friendly, and precise coating removal solution.

The system incorporates multiple high-precision, fast-response sensors—including temperature, distance, color, and material detection modules—to ensure process stability, operational safety, and structural protection of the aircraft during paint removal. It can be widely applied to stand-alone laser cleaning of aircraft components and serves as a technological foundation for future large-aircraft full-body laser paint stripping systems.

Our company has been deeply involved in this project, working in close collaboration with aviation maintenance organizations to provide core laser components and intelligent control systems. Together, we aim to drive technological upgrades in aircraft manufacturing and maintenance, offering a new-generation solution for aircraft surface treatment.