TINY 50-300W Pulsed Laser Cleaning Equipment

- The body is compact and lightweight, and can be carried around with a safety case.

- Auxiliary focusing module, real-time display of processing distance.

- Efficient and non-damaging, suitable for various substrates.

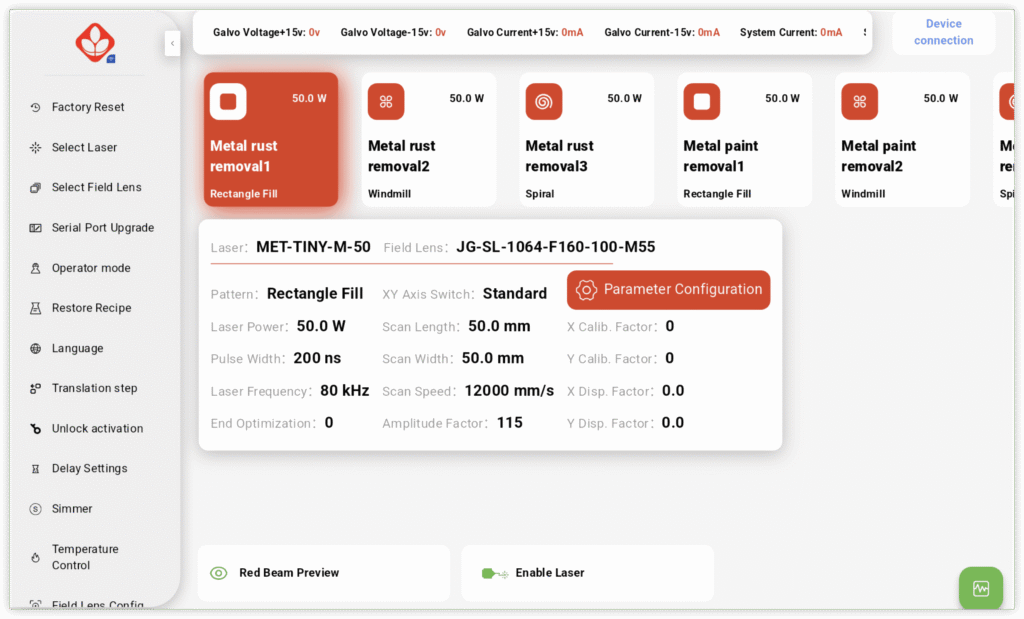

- Red light auxiliary preview, precise positioning of cleaning laser, and convenient adjustment of system parameters.

- Main control options: industrial serial port screen, wireless tablet, mobile phone terminal.

Advantages:

The METLASER MET-INT-QCS-200/300 Internal Diameter Laser Cleaning System boasts adjustable focal length, excellent adaptability, and customizable configurations. Featuring a compact, lightweight laser head, it can be seamlessly integrated with collaborative robots and industrial robotic arms to enable automated cleaning operations.

With user-friendly parameter adjustment and compatibility with multiple control modes, the system efficiently removes rust, contaminants, oil, coatings, and other residues from the inner surfaces of pipes and components. It is widely applicable in industries such as mechanical processing, rail transit, and maintenance of EMUs (Electric Multiple Units) and high-speed trains. Leveraging its adjustable focal length design, the system accommodates various inner diameter specifications while delivering superior cleaning efficiency—making it the optimal solution for your laser cleaning needs.

Innovation and Quality:

At METLASER, driving technological innovation and upholding high product quality standards are our top priorities. All research and development, production and testing processes are completed in a closed loop within its own professional laboratories and standardized workshops, ensuring quality control from the source. Moreover, by leveraging the advantages of wireless networks, it breaks through geographical restrictions to provide immediate and professional remote maintenance and technical support to customers worldwide.

Interface:

The MET-INT-QCS-200/300 Internal Diameter Laser Cleaning System is equipped with I/O ports for seamless integration with automated equipment. Laser emission and shutdown can be directly controlled via a teach pendant.

Control:

The MET-INT-QCS-200/300 Internal Diameter Laser Cleaning System offers multiple control methods, including wireless tablet, robot teach pendant, serial port display, and PLC.

INNER Series | |

Characteristics | MET-INT-QCS-200 |

Working Mode | Pulsed |

Center Wavelength | 1064nm |

Average Output Power | ≤200W |

Maximum Pulse Energy | 2/5mJ |

Pulse Width | 13-500ns |

Adjustable Frequency Range | 1-3000KHz |

Adjustable Power Range | 0-100% |

Output Power Instability | ≤5% |

Cooling Method | Air Cooling |

Output Armored Cable Length | 5m |

Maximum Power Consumption | ≤1000W |

Supply Voltage | AC 110/220V |

Maximum Current | ≤5A |

Operating Temperature Range | 0-40℃ |

Storage Temperature Range | -10-60℃ |

Dimensions of the

Control Unit Cabinet | 483*436*177mm |

Laser Head Parameters | |

Characteristics | MET-INT-QCS-200/300 |

Weight | 0.5Kg |

Outer Diameter | 46mm |

Compatible Connection Method | QCS |

Center Wavelength | 1064nm |

Cleaning Diameter Range | 55-300mm |

Control Mode | Pulse + Direction |

Voltage | 24V |

Current | 60mA |

Rotational Speed | 0-5050rpm |

Processing Speed | 2-5mm/s |

Operating Humidity | ≤80% (Non-condensing) |

Operating Temperature | -15-55℃ |