MAX 500-1000W Pulsed Laser Cleaning System

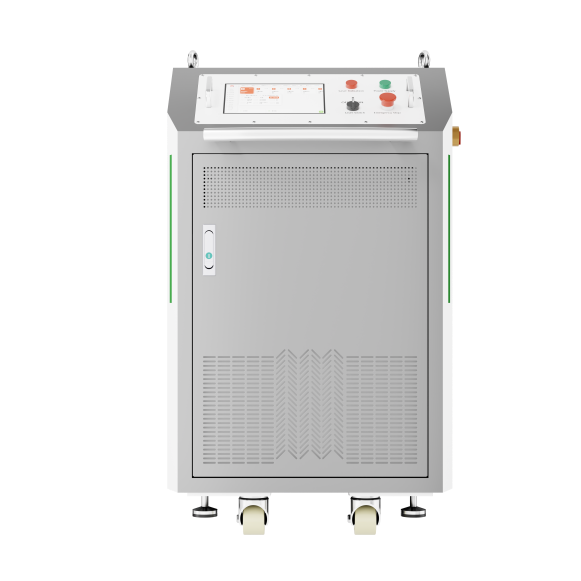

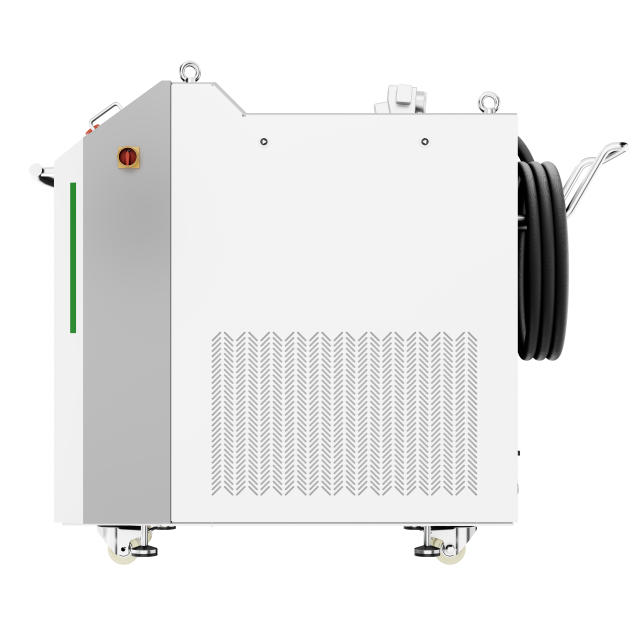

- Integrated equipment design, universal shock-absorbing casters,and excellent mobility

- Non-contact cleaning, high efficiency, non-damage, and Suitability for various substrates

- Laser head auxiliary focusing module, real-time display of processing distance

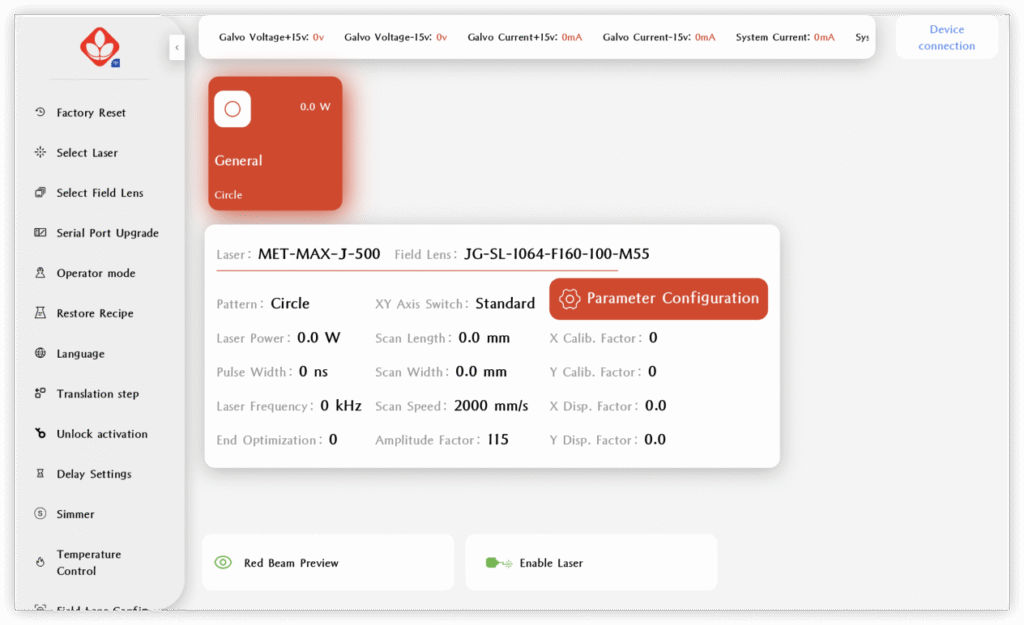

- Red light auxiliary preview, accurate positioning of cleaning laser,and convenient adjustment of system parameters

- Main Control Options: Wireless Tablet, Industrial Serial Screen, Mobile APP

Advantages:

The METLASER MAX Series Pulse Laser Cleaning System boasts numerous advantages, including excellent mobility, a compact and lightweight laser head, convenient adjustment of system parameters, and wireless control. It can efficiently remove rust, stains, oil, coatings, and other contaminants from workpiece surfaces, and is suitable for industries such as mechanical processing, mold cleaning, food processing, and electronic circuits. Leveraging its precise positioning capability, it can accommodate the processing of workpieces with various shapes, achieving a highly efficient cleaning effect.

This cleaning machine leverages the advantages of the MOPA (Master Oscillator Power Amplifier) structure and is equipped with a 500W/1000W cleaning-type pulsed fiber laser as the cleaning light source. This MOPA fiber laser features independently adjustable pulse width and frequency, and can still maintain a high and stable peak power output when the pulse width and frequency are adjusted, so as to adapt to a wider range of cleaning scenarios.

Innovation and Quality:

For METLASER, driving technological innovation and upholding high product quality standards are core priorities. The R&D, production, and testing processes of all products are completed in a closed-loop manner within its self-built professional laboratories and standardized workshops, ensuring quality control from the source. Furthermore, by leveraging the advantages of wireless networks, it breaks geographical limitations and provides global customers with immediate and professional remote maintenance and technical support.

Interface:

The MAX 500-1000W pulsed laser cleaning system is equipped with IO ports that interface with automated devices. The emission and shutdown of the laser can be directly controlled via the teach pendant.

Control:

The MAX 500-1000W pulsed laser cleaning system offers multiple control methods, including a wireless tablet, an industrial serial port display, and robotic IO signals.

MAX Series | |||

500W | 1000W | ||

Characteristics | MET-MAX-J-500-1/5/15/50W | MET-MAX-J-1000-5/15/50W | MET-MAX-J-1000-100W |

Central Wavelength | 1064nm | ||

Maximum Average Output Power | 500W | 1000W | |

Maximum Single-Pulse Energy | 1.5/5/15/50mJ | 5/15/50mJ | 100mJ |

Frequency Range | 1-4000kHz | 10-4000kHz | 10-100kHz |

Pulse Width Range | 30-500ns | 30-500ns | 20-110ns |

Power Adjustment Range | 0-100% | 1-100% | |

Output Power Instability | <5% | ||

Minimum Bending Radius of Optical Fiber | 125mm | ||

Supply Voltage | AC 110/220V | ||

Maximum Power Consumption | 5000W | 7550W | |

Armored Cable Length | 5/10m | 10m | |

Output Head Type | QBH | ||

Operating Temperature | 0-40℃ | ||

Storage Temperature | -10-60℃ | ||

Complete Machine Weight | 150Kg | ||

Cooling Method | Water Cooling | ||

Overall Machine Dimensions | 1052*660*1000mm | ||