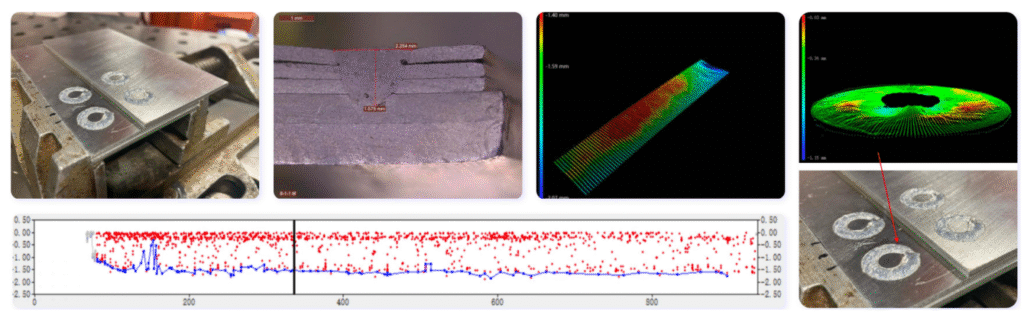

The OCT (Optical Coherence Tomography) real-time melt pool monitoring system utilizes high-speed scanning to capture up to 70,000 measurement points per second, enabling comprehensive inspection of critical areas during the welding process. The system can continuously scan the unwelded joint surface, the melt pool keyhole, and the solidified weld seam—achieving full-process quality monitoring before, during, and after welding.

Equipped with advanced evaluation algorithms and deeply integrated with AI-based analysis, the OCT system performs intelligent assessment and prediction of dynamic melt pool behavior. By combining high-precision data acquisition with intelligent algorithms, the system can identify welding defects in real time, monitor keyhole stability, and optimize welding parameters to improve weld quality and consistency.

Compared with traditional monitoring methods, OCT technology offers non-contact, high-speed, and high-precision advantages. It is well suited for demanding laser welding applications in aerospace, precision manufacturing, and the automotive industry. The system not only enhances welding quality and production efficiency but also provides strong support for the advancement of intelligent and automated welding technologies.