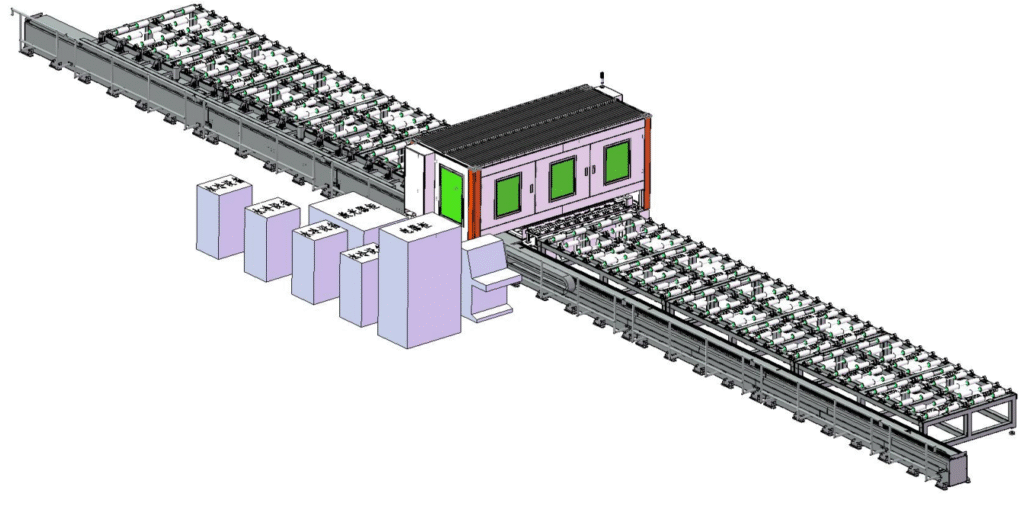

This system is a high-efficiency, intelligent, ultra-large-format multi-laser-head welding platform capable of performing single-sided welding with double-sided forming on dual-layer steel plates up to 20 m × 2 m in size. The equipment integrates multiple innovative technologies—including high-speed galvanometer scanning, a full-nitrogen protected welding process, and high-speed nonlinear control of multi-mover linear motors—to significantly enhance processing efficiency while ensuring superior weld quality.

- High-efficiency welding: The system can automatically complete more than 4,000 weld points, requiring only 20 minutes for the entire welding process—achieving 3.5× higher efficiency than first-generation single-laser-head equipment.

- Precision control: Utilizing high-speed nonlinear control with multi-mover linear motors, the system achieves accurate trajectory tracking, reduces heat input, and enhances overall welding quality.

- Large-format intelligent operation: The welding start reference point is positioned to the left of the Y-axis 2050 coordinate. Side spaces of 1108 mm and 428 mm support weld-head adjustment and routine maintenance. Each laser head can also operate independently.

- High-quality welding process: A full-nitrogen protective atmosphere minimizes oxidation, enhances weld integrity, and meets the requirements of high-strength and long-durability applications.

This system is widely applicable across the energy sector, rail transit, aerospace, and large structural component manufacturing. With its advantages in precision, efficiency, and automation, it provides a reliable and advanced welding solution for large-scale industrial applications.